Power Cleaner KST 2.0

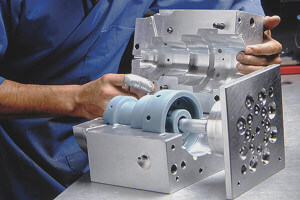

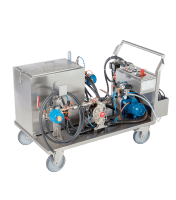

Art.-Nr : A02009Low-foaming, acidic high-performance cleaner, especially designed for mechanical use for cleaning the interior of cooling ducts of injection moulds in combination with the RWR KST (pipe- and heat exchanger cleaning device). The cleaner achieves perfect results in injection-moulding-, aluminium-casting-, and zinc-diecasting processes.

- REMOVES limescale, rust and mineral deposits also from complex mould geometries

- VOC-reduced and free from solvents and hydrochloric acid

- Occupational safety and employee protection are increased

- For cleaning the interior of cooling ducts, tempering units, and systems

- Optimized recipe ► no corrosion, good material compatibility, gentle on the metal of the injection mould

- Ready-to-use

Product Details

- No costly cooling duct widening required

- No downtimes

- Increased mould productivity

- Increased system durability and product quality

Contaminations such as coolant- and refrigerant deposits, limescale, rust and mineral deposits are removed effectively. Occupational safety and employee protection benefit from the VOC-reduced cleaner that is also free from solvents and hydrochloric acid. The longevity of the moulds and systems and the quality of the products are increased. Pre-emptive cleaning results in increased heat exchange, which in turn increases productivity.

Related links to "Power Cleaner KST 2.0"

Seals of approval

- the cleaner is ready-to-use

- Reduced volatile organic compounds

Technical specification

| EAN: | 4024048601827 |

| Label: | Labelled |

| VOC content: | VOC-reduced |

| NSF-certified: | no |

| Contamination: | limescale, mineral deposits, rust, oxidation, tarnishing |

| Material: | aluminium, Plastics, stainless steel, steel, tiles |

| Check material compatibility: | non-ferrous metal, rubber, varnished surfaces, zinc-coated surfaces |

| Cleaner basis: | water-based acidic |

| Mechanics: | automatic parts washing machine, immersion bath, manual cleaning, pipe- & heat exchanger cleaning, ultrasound |

| Manual/automatic: | automatic |

| Concentrate: | ready to use |

| Seal of approval: | Ready-To-Use, VOC reduced! |

| Safety advice: | Skin Corr. 1B |

Field of application

- For cleaning the interior of cooling ducts of plastic injection moulds

- Effectively removes limescale, rust, mineral deposits and light organic contaminations from the cooling ducts

- Efficient removal of deposits also from complex pipe geometries

Usage

| Cleaners | Miscibility | Use with parts washers | Mixing ratios for applications systems | ||||||||

| ↓ | with water | for manual use |

CLEAN BOX |

HTW |

BIO-CIRCLE Turbo |

RWR |

Stainless-steel foam sprayer | Foam Injector | FOAM BOOSTER | Pressure sprayer | Foam sprayer |

| Power Cleaner 150 | yes | 5 % - 100 % | 20 % - 100 % | 5 % - 30 % | 5 % - 30 % | - | - | - | - | 5 % - 100 % | - |

|

Power Cleaner 200 |

yes | 5 % - 100 % | 10 % - 100 % | - | - | - | 60 % - 100 % | 60 % - 100 % | 60 % - 100 % | - | 80 % - 100 % |

| Power Cleaner 300 | yes | 2,5 % - 100 % | 2,5 % - 20 % | - | - | - | - | - | - | - | - |

| Power Cleaner 400 | yes | 5 % - 100 % | 2,5 % - 50 % | 5 % - 30 % | 5 % - 30 % | 10 % - 30 % | - | - | - | - | - |

| Power Cleaner DB | yes | 5 % - 100 % | 2,5 % - 50 % | 5 % - 30 % | 5 % - 30 % | 20 % - 60 % | - | - | - | - | - |

| Power Cleaner KST 2.0 | no | pure | pure | pure | pure | pure | - | - | - | - | - |

Other Recommendations

Viewed

-

-

Low application temperature, energy-saving, water-saving

-

For us, sustainability means taking responsibility

-

-

From renewable raw materials, non-flammable, VOC-free, non-marking

-

-

Suitable for the food industry, miscible with water, can be rinsed without residue

-

-

Free from / reduced volatile organic compounds according to EU regulation